|

|

Холдинг ОСК групп - Российский производитель

систем газового пожаротушения НОВЕК® c применением эффективных огнетушащих веществ (ГОТВ), в том числе:

систем газового пожаротушения НОВЕК® c применением эффективных огнетушащих веществ (ГОТВ), в том числе:

- Газовое огнетушашее вещество ФК-5-1-12

Газовое огнетушащее вещество под наименованием

«ФК-5-1-12», входит в перечень разрешенных веществ, для которых в РФ разработаны стандартные нормы и правила их использования в автоматических установках газового пожаротушения (АУГПТ), СП 485.1311500.2020.

Внимание!

По всем вопросам обращайтесь в Единый центр поддержки клиентов по тел. +7(495)785-55-01, e-mail 01@novec-1230.ru |

|

Испытания модулей пожаротушения на сейсмоударопрочность и сейсмостойкостьИспытания оборудования для систем газового пожаротушения НОВЕК® проводились на сейсмоударопрочность при воздействии ударного ускорения с амплитудой 20g и сейсмостойкость к воздействию землетрясений интенсивностью 9 балловИспытания модулей пожаротушения на сейсмоударопрочность и сейсмостойкость |

|

Испытание баллона для газового пожаротушения БП 187 на разрывПроведенные испытания на основе научных расчетов доказывают, что баллоны, используемые в составе модулей газового пожаротушения НОВЕК®, являются одними из самых надежных не только в России, но и в миреИспытание баллона для газового пожаротушения БП 187 на разрыв |

|

Верификация гидравлического расчета системы пожаротушения 3 насадкаПроведены совместные работы с ФГБУ ВНИИПО МЧС России по верификации гидравлического расчета распределительной трубопроводной сети модульных автоматических установок газового пожаротушения НОВЕК®Верификация гидравлического расчета системы пожаротушения 3 насадка |

|

Заправка модулей газового пожаротушения ГОТВ на заправочной станции Холдинг ОСК группЗаправочная станция по заправке баллонов газовыми огнетушащими составами (ГОТВ). Одна из крупнейших заправочных станций в России. Заправляем эффективные огнетушащие вещества (ГОТВ)Заправка модулей газового пожаротушения ГОТВ на заправочной станции Холдинг ОСК групп |

|

Высокоэффективное огнетушащее вещество для тушения пожаров

Эффективное действие подавления огня, выпуск огнетушащего вещества ФК-5-1-12 и тушение пожара занимает менее 40 секунд. Любое горение твердых и жидких веществ, металлов, электроустановок не оставляет никаких шансов пожару.

Безопасное огнетушащее вещество для электронной техники

Огнетушащий состав не проводит электрический ток, не приводит к коротким замыканиям и не оставляет следов на электронном оборудовании. После применения не требуются дополнительные меры для очистки.

Огнетушащее вещество безвредно для окружающей природы

Огнетушащий агент не содержит в себе элементов брома и хлора и под воздействием солнечного излучения испаряется за 5 дней. Вещество не оказывает опасного воздействия на климатические и атмосферные процессы, не воздействует на экологию и полностью безопасно для озонового слоя.

Огнетушащее вещество безопасно для здоровья человека

Огнетушащий агент при его применении не поглощает кислород, не оказывает опасного воздействия на кожу, не раздражает слизистые оболочки. Обладает минимальной концентрацией, органы зрения и дыхания человека остаются вне опасности.

Система газового пожаротушения компактна для размещения

Для автоматической установки на объекте потребуется минимальное пространство и место в помещении. Минимум пространства и простота монтажа оборудования делают такую систему простой и незаменимой в совершенно любых архитектурных сооружениях.

Огнетушащее вещество удобно для транспортировки

Вещество для пожаротушения перевозится без маркировки «опасный груз» в жидком состоянии. Мобильные заправочные станции позволяют заправлять модули газового пожаротушения прямо на объекте.

Эффективное действие подавления огня, выпуск огнетушащего вещества ФК-5-1-12 и тушение пожара занимает менее 40 секунд. Любое горение твердых и жидких веществ, металлов, электроустановок не оставляет никаких шансов пожару.

Безопасное огнетушащее вещество для электронной техники

Огнетушащий состав не проводит электрический ток, не приводит к коротким замыканиям и не оставляет следов на электронном оборудовании. После применения не требуются дополнительные меры для очистки.

Огнетушащее вещество безвредно для окружающей природы

Огнетушащий агент не содержит в себе элементов брома и хлора и под воздействием солнечного излучения испаряется за 5 дней. Вещество не оказывает опасного воздействия на климатические и атмосферные процессы, не воздействует на экологию и полностью безопасно для озонового слоя.

Огнетушащее вещество безопасно для здоровья человека

Огнетушащий агент при его применении не поглощает кислород, не оказывает опасного воздействия на кожу, не раздражает слизистые оболочки. Обладает минимальной концентрацией, органы зрения и дыхания человека остаются вне опасности.

Система газового пожаротушения компактна для размещения

Для автоматической установки на объекте потребуется минимальное пространство и место в помещении. Минимум пространства и простота монтажа оборудования делают такую систему простой и незаменимой в совершенно любых архитектурных сооружениях.

Огнетушащее вещество удобно для транспортировки

Вещество для пожаротушения перевозится без маркировки «опасный груз» в жидком состоянии. Мобильные заправочные станции позволяют заправлять модули газового пожаротушения прямо на объекте.

Системы газового пожаротушения ОСК ГРУПП ®

Холдинг ОСК групп является высококвалифицированной организацией и осуществляет производство автоматических установок газового пожаротушения (АУГПТ), поставку, работы по монтажу, ремонту и обслуживанию средств обеспечения пожарной безопасности строительных объектов на основании имеющихся сертификатов, лицензий и свидетельств.В собственности имеются производственные цеха, в которых изготавливают оборудование для газового пожаротушения, большой склад комплектующих. Оборудование для пожаротушения под маркой ОСК ГРУПП ® для газового пожаротушения сертифицировано в системе ГОСТ Р и Технического Регламента Таможенного Союза.

Выполненные объекты

Холдинг ОСК групп работает на территории Российской Федерации и стран Таможенного Союза ЕАЭС более 20 лет.Наши клиенты »»»

Выполненные объекты »»»

Российские и международные компании, доверили нам более 300 объектов для организации на них пожарной безопасности современного типа.

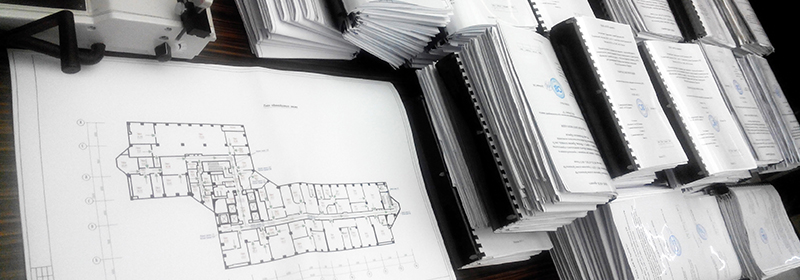

Объекты Холдинга ОСК групп, на которых были выполнены работы по поставке, монтажу, вводу в эксплуатацию систем пожаротушения.

Холдинг ОСК групп гарантирует выполнение всех требований пожарной безопасности и сдачу объекта ГОСКОМИССИИ.

Объекты Холдинга ОСК групп, на которых были выполнены работы по поставке, монтажу, вводу в эксплуатацию систем пожаротушения.

- - Объекты нефтегазового комплекса

- - Объекты культурного наследия

- - Объекты транспорта

- - Объекты IT-инфраструктуры (серверные, ЦОД)

- - Объекты промышленности

- - Банки, архивы, хранилища

- - Бизнес-центры, комплексы

- - Объекты Кремля, УДП

- - Прочие объекты

Холдинг ОСК групп гарантирует выполнение всех требований пожарной безопасности и сдачу объекта ГОСКОМИССИИ.

скорбим со всей страной...

Газовое огнетушащее вещество (ГОТВ) под наименованием «ФК-5-1-12» входит в перечень разрешенных веществ, для которых в РФ разработаны стандартные нормы и правила их использования в автоматических установках газового пожаротушения (СП 485.1311500.2020).

Клапан обратный ОК «Брандсис» предназначен для обеспечения работоспособности установок газового пожаротушения при подаче ГОТВ из отдельных модулей или групп модулей батареи, а также для автоматического предотвращения обратного потока ГОТВ.

Распределительное устройство РУП 100 «БРАНДСИС» применяется в централизованных АУГП при монтаже на трубопроводном коллекторе в станции пожаротушения, в том числе, в составе судовых стационарных газовых системах пожаротушения.

Запорно-пусковое устройство «БРАНДСИС 0421» обеспечивает герметичное хранение ГОТВ под давлением газа-вытеснителя, а также выпуск ГОТВ в разводку трубопроводов АУГПТ при срабатывании ЗПУ.

Запорно-пусковое устройство «БРАНДСИС 0418» обеспечивает герметичное хранение ГОТВ под давлением газа-вытеснителя, а также выпуск ГОТВ в разводку трубопроводов АУГПТ при срабатывании ЗПУ.

Данная станция способна обеспечить азотом производимые и заправляемые модули МПА-КД в объеме всей отрасли установок газового пожаротушения России.